Complete Water Ring Pelletizing for Waste Plastic Recycling

Descrição do produto

Complete Water Ring Pelletizing for Waste Plastic Recycling

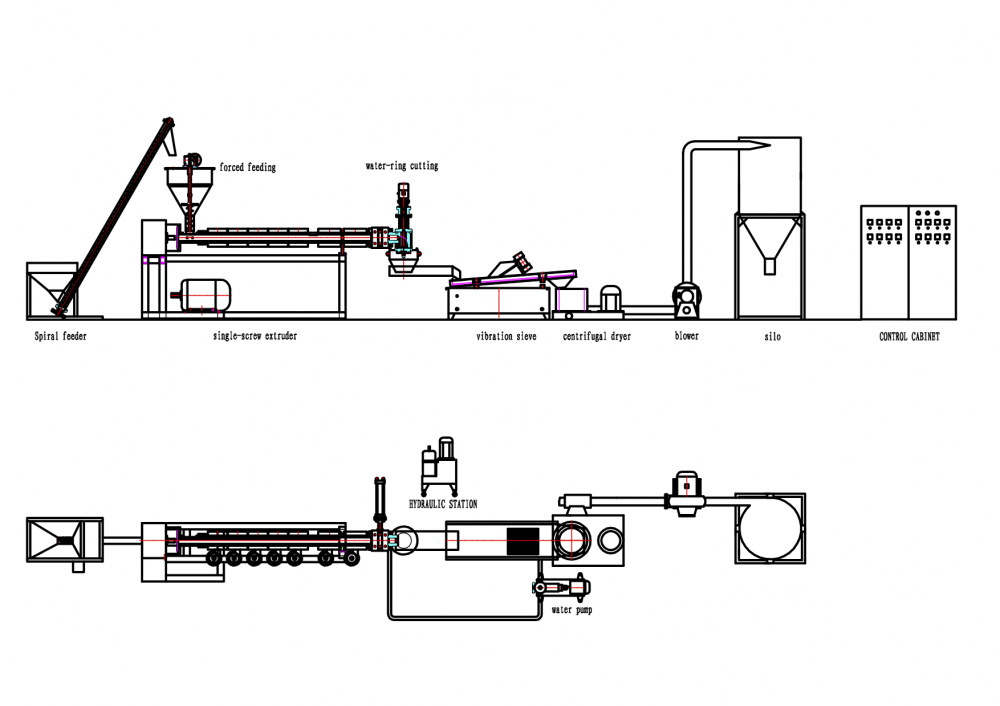

This granulating line is mainly consists of:

1. Belt conveyor: feed the clean films or bags into the cutting compactor

2. Metal detector: check whether there is metal in the films or bags, protect the blades of cutting compact and screws

3. Cutting compactor: cut the materials again and make materials shrink, then force feed the shrunk material into the extruder. For the same capacity, the power consumption is only 50% of the agglomerator.

4. Single screw extruder: for plasticizing the materials and exhausting the gas, it is made of 38CrMoAlA generally.

5. hydraulic screen changer: filter the impurities, improve the granules quality

6. Water ring Pelletizer: includes mould and pelleting blades, we can provide both vertical type and horizontal type.

7. Water cooling tank: use circular water for cooling the granules immediately after pelleting cut.

8. Vertical dewatering machine: convey the granules helically from bottom to top, the rotary rotor and the stainless screen help to drain the water, and convey the granules out from the machine

9. Vibration screen: to filter out non-standard pellets and get even uniform quality pellets.

10. Blower system: use the blower to blow the granules to the storage silo through the SS304 pipe.

11. Storage silo: for storing the final pellets.

12. Control system: use SIEMENS contactor, Omron temperature controller, ABB or FUJI inverter and SIEMENS BEIDE China famous electrical components.

Route for customized pipe production solution

· Customer expectation

· Schematic extrusion process

· Plant and Resource check

· Technical Specifications for Production line

· Production of machine

· Selection of Suppliers

· Coordination with Suppliers

· Manufacturing of Machine

· In-House test running

· Confirmation of Shipping date

· Assembly and Handover of Production Line

· Operation Training

· After Sales Service

Grupo de Produto : Equipamento de Reciclagem de Plástico > Linha de Reciclagem de Filmes